Hot Deals

Best Sellers

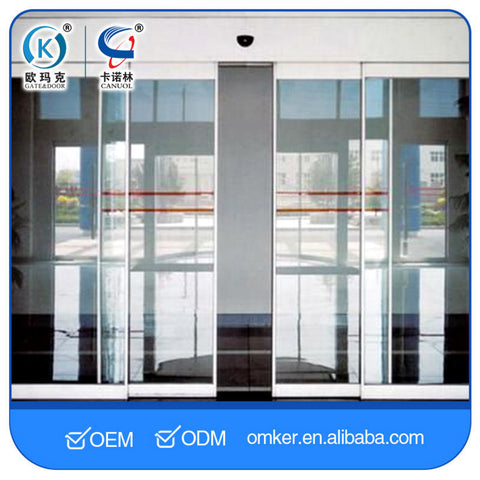

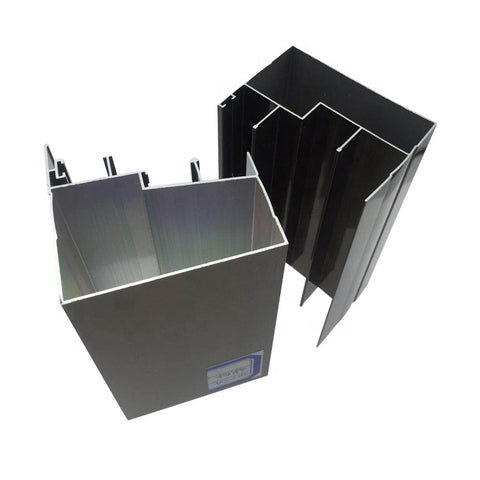

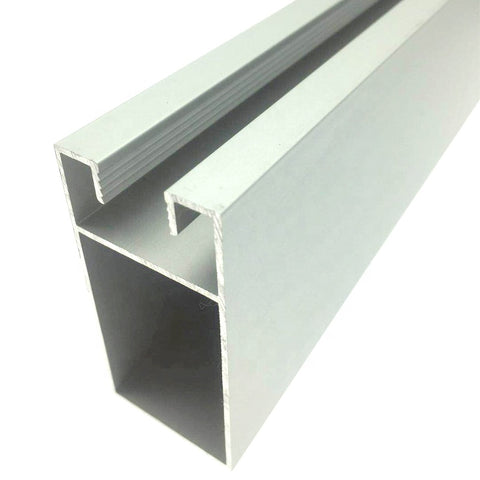

Secure door coating line on China WDMA

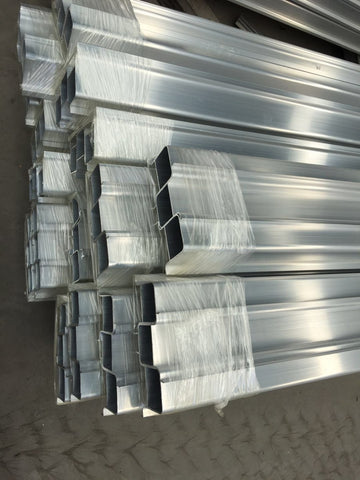

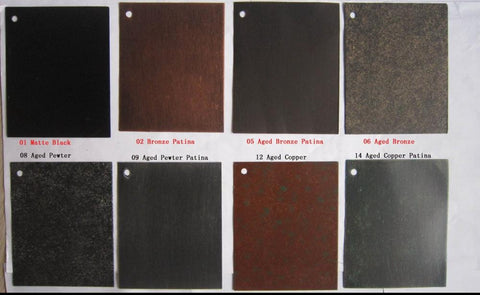

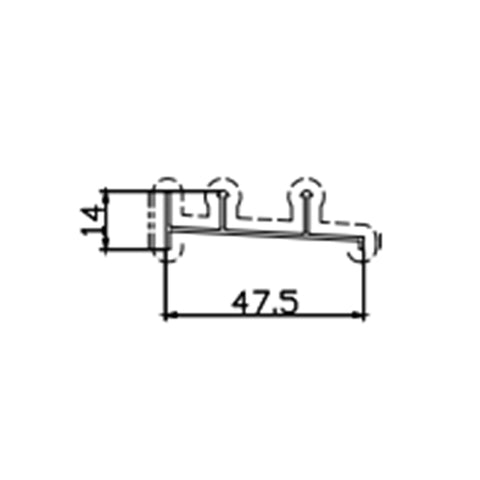

Product Description Name Automatic paint painting production line: Put the product into the automatic conveying line, pass the preheating zone, dust removal zone, spray painting zone, drying zone and other processes. After the completion, remove the product. Automatic painting machine Painting robot, multi-directional motion painting robot, such as...

Please write your review of Secure door coating line on China WDMA.