Hot Deals

Best Sellers

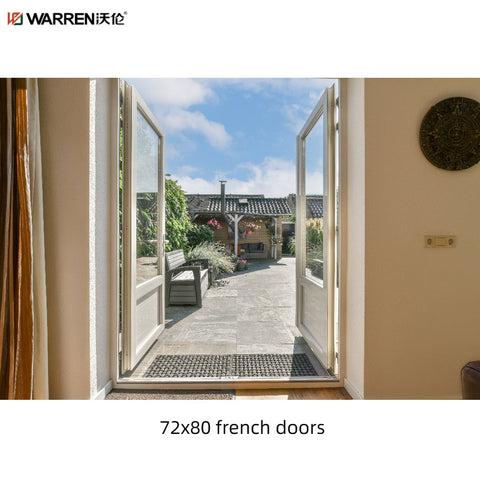

Customized PVC UPVC PP Ceiling Roof Board Extrusion Mould Maker Plastic Panels Mold on China WDMA

Customized PVC UPVC PP Ceiling Roof Board Extrusion Mould Maker Plastic Panels Mold Product Description Specification: Mould Name Customized window and door profiles extrusion mould Brand Hubei Huangshi Zhongtai Plastic Mould Manufacturing Co.,Ltd Extrusion mould material 3Cr13,3Cr17,din1.2316 stainless steel Mould component die head, calibrator, water tank ,heating...

Related Products

Recently Viewed Products

You may also like

Please write your review of Customized PVC UPVC PP Ceiling Roof Board Extrusion Mould Maker Plastic Panels Mold on China WDMA.